|

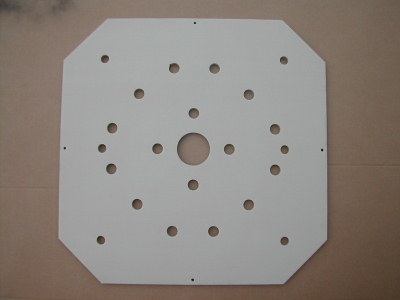

Insulating Plates ISOL 210

|

Press

of 190 tons |

|

As everyone knows, the insulating plate is installed between the machine plan and the heating plan (on which is mounted the mold). During the injection phase of the rubber, the pressure that develops in the central part of the plane is very high, so that the insulating plates are compressed to a few hundredths of mm, but also the machine plan at the center undergoes a slight flexion. This situation entails the drawback that the mold, in the central part, tries to debur; the solution normally used is to put a thickness under the mold; according to need can be inserted from 0,05 to 0,30 mm (lesser is the thickness of the mold, higher the need of shimming).

|

|

|

|

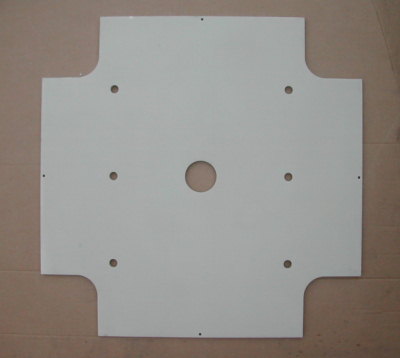

Press

of 270 tons |

|

In this case, however, is not considered necessary to insert the ring of reaction, since the molds that will be mounted, being of considerable thickness, will not be the bending of the plans. |

|

|

|

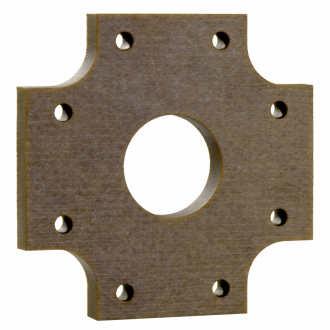

Press

of 270 tons |

|

The insulating plates are provided by us already cut according to the customer's design, having a multilayer composite fiberglass impregnated with resins very hard and high density, the user would find it difficult to cut with the normal machine tools, while with our system "water-jet", as seen in the picture, we can cut perfectly any shape. |

|

|

|

The insulating plates

ISOL 260 are recommended for those horizontal presses normally dedicated to the production of O-Rings, with compounds accelerated so as to take high temperatures molds

(~220°C) and very short cycles (20"÷25"). |

|

Unfortunately, even today many constructors of presses, uses insulating plates very economic just to save a few hundred Euros, thus affecting the quality of

closure. |

|

|

For Technical

Consultancy - Inquiries - Orders: |

|